Add to Cart

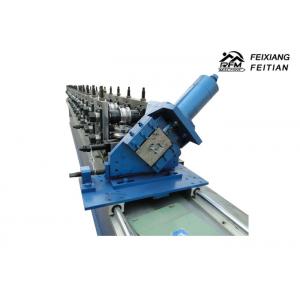

Figured metal stair handrail roll forming machine with punching holes

Production Process

Decoiling - leveling - punching - forming - cutting - finish product

Components of the whole line

| No. | Item | Unit | Qty |

| 1. | Decoiler | set | 1 |

| 2. | Feeding and leveling device | pcs | 1 |

| 3. | Main forming machine | set | 1 |

| 4. | PLC Control box | set | 1 |

| 5. | Hydraulic pump | set | 1 |

| 6. | Cutting system | pcs | 1 |

| 7. | Output table | pcs | 1 |

Technical Parameters

Suitable material: Stainless steel

Thickness:0.3-1mm

Feeding width: as request

Working speed:6-12m/min

Detailed description of every parts

a. 5T hydraulic decoiler:

(1). Material coil inner diameter: 450mm-550mm

(2). Max coil Width:550mm

(3). Carrying capacity: 1.5T

b. Feeding and leveling device

(1)Feeding roller: two rollers with adjust hand wheel.

(2)Leveling shaft: two shafts with diameter 50mm.

(3)Function: Make the sheet feed into machine smoothly.

c. Main forming machine

(1) Main frame material:25mm column plate, The main frame of machine is welded separately and the outside wall is connected by screw after polishing on the surface.

(2) Number of forming steps:18steps with vertical rollers.

(3) Roller material:Cr12 steel with quenching, The rollers are machined by the exact machine tool. So that ensure long life of forming rollers

(4) Shaft material:Cr40 steel ,Diameter:50mm, Shafts are tooled by grinding machine for two times to ensure time forever.

(5) Transmission style: Gear move the line, electric motor drives. All working actions are controlled by PLC electric cabinet automatically.

(6) Voltage:380v50hz3p or as your request.

(7)Main drive motor power:5.5kw.

(8)Gear safety cover: Available.

d. PLC control box

(1) PLC: Delta, automatic control the whole system, easy to operate

(2) Frequency transformer: Delta

(3) Reducer: Chinese brand

(4) 5.7inch operate screen

(5) Encoder: Chint

e. Cutting system

(1) Adopt to stop cutting, advanced hydraulic drive, automatic cutting after forming, no distorting, high level safety factor.

(2) Cutting mold:3 blade. blade material Cr12 with heat treated .

(3) Cutting length tolerance ±1mm. The power of cutting is provided by hydraulic station

(4) The final product can be cut as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the product automatically. Finish this action, machine will run again continuously

f. Hydraulic pump

(1) 1 set ,with power 4kw

(2) Include a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes(It supplies the power for the hydraulic cutter). And two sets of electromagnetism valves ,one pressure guage

(3)Hydraulic oil:46#

g. Simple run out table

(1) 1 pieces, welded by 60*40mm square steel pipe, size 3 meters

(3) The height can be adjusted, we can also design as your special request

Notes:

(1) Date of delivery: Within 45 working days after receipt of the deposit

(2) Warranty period: 1 year, life–long provides the technical guidance

(3) Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD100/person/day for salary.

(4) Need one technicians

(5) Training time: one week (contains the time of installation and adjustment)

(6) We provide Spare part for machine: Easy damaged parts: conk 2 pcs, fuse-link 4 pcs ,Rubber mat 1 pcs, Bolt spanner 1 pcs